Ravellings on the knitted

sleeve

Part II - Creating a set-in sleeve for

a sleeveless body

The whys and wherefores

of set-in sleeves

Depending on the intended

style of a garment, a drop shoulder or modified

drop shoulder is simply less desirable or

attractive. For certain styles, such as tailored

and close-fitting styles, a set-in sleeve

is the most appropriate sleeve to use. To

understand why a set-in sleeve succeeds where

other styles fail, we need to examine why

the set-in sleeve is shaped the way it is.

Parts of the archetypal set-in sleeve

Like any other sleeve, the

forearm and upper arm is covered by a main

portion that extends from the wrist (if the

sleeve is long) to the biceps line, which

can be considered the beginning of the underarm.

The remainder of the set-in sleeve -- the

cap -- extends from the biceps line to the

shoulder and has a generally bulbous shape.

Following the outline of the cap from the

biceps line to the shoulder, you can see that

the slope of the outline changes. At the biceps

line and shoulder, the slope is pretty much

horizontal; between the biceps line and the

shoulder, the angle of the cap is first shallow,

then steep, then becomes shallow again.

|

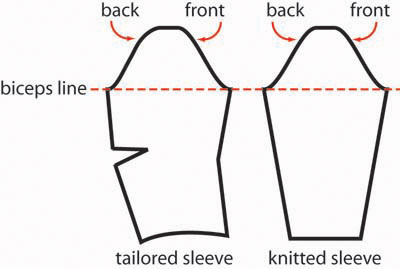

| The garden-variety set-in

sleeve. At the left, the front and back

of the tailored sleeve cap are shaped

with more accuracy than is usually applied

in knitting; the back is cut larger to

accommodate the shoulder blade. Finely

tailored sleeves may also be fitted at

the elbow with darts or ease. In typical

knitted set-in sleeves, right, the front

and back halves of the sleeve are mirror

images, with no differences in dimension,

and no special shaping at the elbow. |

The perimeter of the sleeve

cap is sized to fit into the armscye (armhole)

of the body, either exactly or with a little

excess fabric in the cap that needs to be

distributed along the armscye seamline. In

a properly fitted garment, particularly in

garments sewn from woven cloth, the sleeve

cap is shaped differently towards the front

and back of the body, and the armscye cut

into the body is cut deeper in front than

in the back. This difference accommodates

the shape of the shoulder blade better than

a perfectly symmetric sleeve and armscye.

Optionally -- and this was a more common feature

in women's clothing until the mid-twentieth

century or so -- shaping can be added at the

elbow to conform to the arm's natural shape.

However, as you've probably

noticed, in hand knitting the typical set-in

sleeve does not have quite such sophisticated

shaping. The top of the sleeve is finished

with a horizontal edge (the final bind-off

row). Most set-in sleeves are completely symmetric;

there is no elbow shaping, and the back and

front halves of the sleeve cap are identical.

And since hand-knit fabric usually stretches,

we can take advantage of a small degree of

forgiveness in the garment shape, and skip

the step of precisely tailoring sleeve and

armscye. In fact, some set-in sleeve caps

are shaped with a constant slope. Normally,

hand knit set-in sleeve tops are still sufficiently

loose fitting that the lack of asymmetry goes

unnoticed.

Why does a set-in

sleeve work?

The key to a properly fitting

garment is that it has enough ease to allow

you to move as you wish. In a loose-fitting

garment, that ease is all over the place;

there's lots of room in the tubes that act

as sleeves, and lots of room in the tube that

serves as a body, as well. But in a closer-fitting

top, the ease has to be distributed strategically

to provide space without excess fabric. In

a set-in sleeve, the key is in the cap.

Have you ever tried on a

top (either purchased or laboriously knitted

by you) and felt a "binding" sensation

under the arm? Did the shoulders feel tight?

This might have been due to insufficient wearing

ease in the shoulder area. For example, the

distance from your neck to your elbow, over

your shoulder, is shorter when your muscles

contract and your arm is extended straight

out from your side. When your shoulder is

relaxed, with your arm hanging down in the

usual position, the distance over your shoulder

from your neck to your elbow is longer. The

difference in distances isn't large, but it

contributes to the binding feeling of a too-tight

armscye and sleeve. A garment with sleeves

needs to accommodate these little changes

in body dimension as the wearer moves his

or her arms.

In a really loose-fitting

garment, like a drop-shoulder sweater, there's

so much space between the garment and body

that there's no need to tweak the sleeve/shoulder

area to make this accommodation. But in a

tight-fitting garment, something's got to

give. If there isn't enough fabric to fit

or stretch around the body, the result is

that tight, binding feeling.

If a typical modified-drop-shoulder

pullover is designed to be close-fitting,

you may run into that binding problem, particularly

with thicker knit fabrics. If you design the

pullover to fit your body in the pullover's

"relaxed" position -- that is, with

the sleeves extending at right angles from

the body -- it may fit you perfectly as long

as you pose like a woolly board. But when

you lower your arms, you'd find you need more

space for your shoulders. The obvious place

to build in that extra space is, of course,

the upper part of the sleeve -- the sleeve

cap. If the pullover was not so close fitting,

then that binding may not occur at all, meaning

there is sufficient space for your shoulders.

This suggests that a closer-fitting sleeve

needs a deeper sleeve cap.

Also, compare the way you

typically stand and move with the typical

shape of a drop-shoulder or modified-drop-shoulder

garment. Normally, your hands are down by

your sides, or at least, your upper arm is

not extended at right angles to your body.

This suggests that a better-fitting garment

would reflect the relative position of your

arms to your body in real life, something

far less than a right angle to the body. Also,

as mentioned earlier, in a drop or modified-drop-shoulder

garment (assuming the fit is not close or

tight), when the arms are lowered, excess

fabric builds up in the underarm area. This

means that, rather than having a sleeve cap

that is perpendicular to the armscye, the

sleeve will fit better if the cap meets the

body at an angle smaller than a right angle.

This suggests that a closer-fitting sleeve

cap needs to be angled, rather than boxy.

Finally, the practicality

of fitting square pegs in round holes should

be considered. If a sleeve is designed to

have a deep, angled cap, it would probably

look like this:

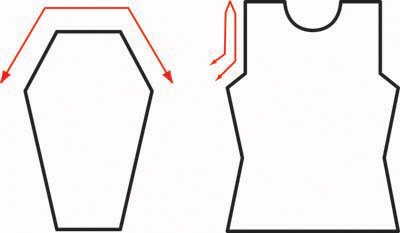

|

| A first draft

of a fitted sleeve, and the armscye it

would fit. |

While the total perimeter

of the sleeve cap is still equal to the perimeter

of the armscye, that bind-off distance across

the top, unlike the drop or modified-drop-shoulder

sleeve, is no longer equal to the vertical

drop of the armscye. Those two corners in

the sleeve cap fabric would have to be sewn

somewhere to the vertical portion of the armscye

-- not an easy thing to do, and not particularly

attractive. This suggests that to have a smoothly

fitting sleeve, the sleeve cap should

be gently curved from underarm to shoulder

point, rather than abruptly angled.

And of course, the human

figure isn't rectangular; it's curvy. The

imaginary line demarcating the body-arm boundary

isn't a box, so why knit one? A more refined

sleeve and body, then, would look something

like this:

|

| A second

draft of the fitted sleeve, and the armscye

it would fit. |

And we've arrived at the

familiar set-in sleeve shape.

A little more theory

By merely inspecting the

respective shapes of the armscye and sleeve

cap, it's easy to see that the method of calculating

set-in sleeve shaping must be more involved

than a simple drop shoulder or modified-drop

shoulder. The geometry is more advanced; the

curved or sloped sides of the sleeve cap must

fit into the straight edge of the armscye,

and some fixed number of stitches at the very

end must be bound off without creating corners

of fabric that are too troublesome to sew

into the armscye. As for the main part of

the sleeve itself, sufficient ease must be

built into the sleeve, but not so much or

so little that the sleeve looks disproportionate

to the garment body; and the length, including

the depth of the cap, must be chosen to hit

the wrist (in the case of a long sleeve) at

just the right point.

In fact, different designers

and pattern drafters have different techniques

for calculating set-in sleeves to fit a given

armscye, and follow different rules of thumb

for:

-

determining the height

of a sleeve cap;

-

deciding whether the

sleeve cap shaping should have a constant

slope or a varying slope;

-

deciding how many stitches

to bind off at the top of the sleeve cap.

These different rules of

thumb vary according to what numbers are fixed

or calculated first. Some designers establish

the height of the sleeve cap first, while

others fix the number of stitches to be bound

off before considering the height or the slope.

As a general rule, however, the shaping and

fit of a plain set-in sleeve is dictated by

the shaping and fit of the body: if the body

is close fitting, the sleeve is close fitting

and the sleeve cap is proportionately deeper;

if the body is loose fitting, the sleeve is

loose fitting and the sleeve cap is shallower.

Exceptions are made, of course, for sleeve

style variations, such as pleated or gathered

caps.

Other matters, such as how

the biceps measurement, circumference of the

wrist, length of the sleeve, or location of

the underarm are determined, are sometimes

handled differently by various designers,

but the end result is the same.

Begin with taking

measurements

The sleeve design is premised

on certain dimensions:

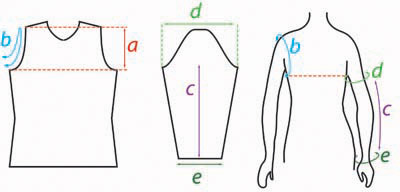

|

| Measurements

for drafting a set-in sleeve pattern. |

| Working

from an existing sleeveless top pattern

If

you are starting from a sleeveless top

pattern, choose a design with armholes

that approximate the shaping of a set-in

sleeve top:

-

an

armscye beginning within an inch

or two of the wearer's underarm

(more, if the garment is loose fitting)

curving as it emerges from the underarm

until it forms a more-or-less vertical

line over the shoulder; and

-

shoulder

coverage extending from the shoulder

line, or near the shoulder line,

towards the neck (the amount of

shoulder coverage depends on the

width of the neckline).

A

halter top does not have the same amount

of shoulder coverage, and the armscye

is often always angled towards the neck.

Strappy and strapless tops don't have

an armscye at all, although if the straps

of a strappy top are positioned near

the shoulder line, you can treat the

underarm-strap assembly as an armscye

for a set-in sleeve. (You may find that

skinny straps positioned so close to

the shoulder will tend to slip off,

making them useless for holding up a

set-in sleeve. In that case, consider

widening the straps to cover more of

the shoulder and adding means to fix

the garment straps to the straps of

your underpinnings.) |

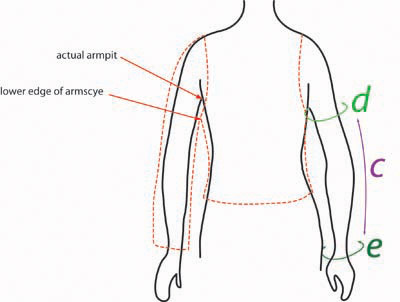

a) the armscye depth on

the garment body;

b) the armscye perimeter

on the garment body;

c) the length of the arm

from armscye to wrist (if the sleeve is meant

to be that long);

d) the width of the sleeve

at the biceps line; and

e) the circumference at

the wrist (or the circumference at the lower

edge of the sleeve, if the sleeve is not wrist

length).

With the exception of the

armscye dimensions a and b, these measurements

are based on actual body measurements, plus

or minus ease. The amount of ease depends

on the overall style and fit of the garment.

Often, the body fit and design has already

been established, so the amount of sleeve

ease will be determined based on the body

ease.

Let's assume you are starting

from an existing sleeveless top pattern. From

its schematics, or from counting the rows

in the armscye, you can work out the depth

of the armscye, a. Make

a note of that value. Although measuring the

perimeter of the top's armscye is likely not

possible without some trigonometric number

crunching or drawing the pattern schematic

to scale, you can at least make a note

of the number of stitches bound off at the

beginning of the armscye on one side

and arrive at a rough estimate of the total

perimeter of the armscye. You can also verify

the fit of the armscye by comparing the measured

depth a with your actual body measurement.

In a standard fitting garment, the armscye

ends about 1 inch below the actual armpit--more,

if the yarn is bulky or you intend to wear

loose shirts underneath the garment. Also

make a note of the distance between the

actual armpit and the lower edge of the armscye.

This value will be used to determine the length

of the sleeve.

|

| The distance

between the actual armpit and the lower

edge of the armscye will be used to calculate

the length of the sleeve. |

A word of caution about

working from an existing sleeveless top pattern:

the set-in sleeve seam is typically expected

to lie across the shoulder point, and the

armscye perimeter is generally loose enough

to allow for comfortable wear and freedom

of movement. However, sleeveless tops are

often cut to expose a little more shoulder,

and a little less armpit. This means that

you may need to adjust your existing pattern

to decrease fewer stitches at the armscye

shaping so that the upper back width is equal

to your shoulder-to-shoulder measurement,

and to drop the lower edge of the armscye

so that there will be sufficient ease to fit

a sleeve.

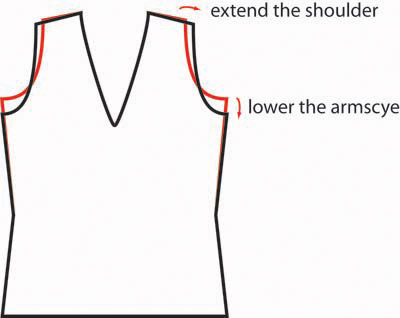

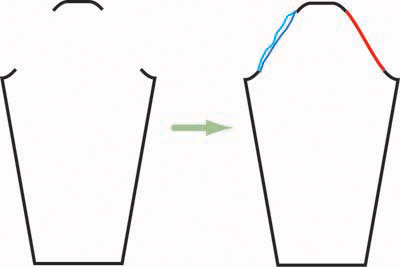

|

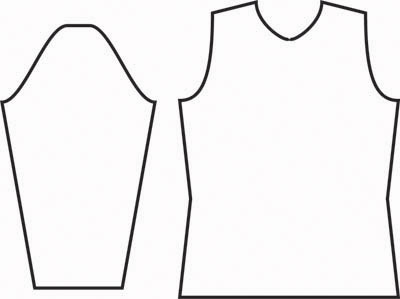

| Some sleeveless

top patterns may need adjusting (from

the red outline to the black outline)

if a set-in sleeve is to be added. |

The length of the sleeve

from armscye to wrist, c,

is not the same as the total length of the

sleeve from the top of the sleeve cap to wrist.

This particular measurement is measured essentially

from the garment's "armpit" to the

wrist. For this value, measure from the

wrist, over a slightly bent elbow, and up

to your actual armpit, and then subtract the

distance you measured above, between the actual

armpit and the lower edge of the garment armscye.

Also from the existing pattern

schematic for the top, make a note of the

total ease around the bust or chest (that

is, the difference between the actual body

measurement and the garment measurement at

the widest point at the chest. For a plain

set-in sleeve, the width of the sleeve

at the biceps line, d, will

be the circumference of the upper arm at its

widest point plus about 50-100% of the body

ease. This 50-100% of the body ease,

in a "standard fitting" garment,

is typically 1 or 2 inches. For a styled sleeve,

like a puffed or gathered sleeve, the width

at the biceps line may be far greater than

this amount.

| Ease

varies over time

If

you consult a number of reference books,

the amount of ease in the body will

fluctuate according to the silhouettes

in vogue at the time the book was published.

Sweaters

from the 1980s and early 1990s, for

example, had loose, easy-fitting styles,

and consequently an "average"

fitting sweater would have at least

4 inches of ease. In the late 90s and

early 00s, a fashionista would have

chosen a closer fit as an "average"

fitting sweater.

This

means, when reading garment descriptions,

you should be aware that a "classic"

or "standard" fit may not

be what you consider to be your classic

or standard. In this article, "classic"

is assumed to be 2 inches of ease. |

Finally, the wrist circumference

e is generally taken to be

either the actual wrist measurement plus 1

inch, or a measurement sufficient to pass

over a closed fist.

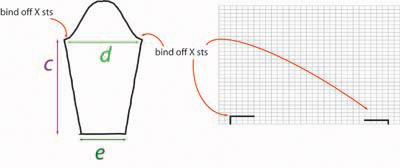

Sketch your schematic

and write in the measurements you know

Sketch a large schematic

of the sleeve, approximating the shape

of the sleeve cap. If you are using proportional

graph paper, don't bother graphing the entire

sleeve to scale--the main part of the sleeve

is quite straightforward. Save the graph paper

for sketching the cap alone. Make a note of

your stitch and row gauge (number of stitches

and rows per inch) on your schematic, as well

as some of the measurements you've taken so

far: the length of the sleeve c,

the width of the sleeve at the biceps line

d, and the circumference at the wrist

e.

Convert the numbers

you have to stitches and rows

With your knitting gauge,

convert the measurements you've written

on the schematic to stitch and row counts,

adding a selvedge stitch or two. At this point,

you'll be able to work out the increases for

the main part of the sleeve, just as the sleeve

shaping was calculated in last

issue's article. In this article, we'll

skip the addition of a cuff, and just work

straight up from the wrist.

Also, at this point, at

the start of the sleeve cap, make a note

of how many stitches to bind off the first

two rows of the sleeve cap. One of the

more constant rules of thumb in knitwear design

is that the number of stitches bound off at

the beginning of the garment armscye equals

the number of stitches bound off at the beginning

of the first two rows of the set-in sleeve

cap.

If you are using proportional

graph paper, now's the time to mark off the

beginning of the sleeve cap, and the first

two rows of the cap shaping.

|

| The schematic

so far, left; and the proportional graphed

sketch so far, right. |

Design the sleeve

cap to fit the armscye

Next, the sleeve cap shaping

needs to be determined. This is where the

design technique can vary. Some designers

will proceed in the following order:

-

Fix the height of the

sleeve cap.

-

Fix the number of stitches

for the final bind-off of the sleeve cap.

-

Decide how to work the

decreases to fit between the initial bind-offs

and the final bind-off, so that the sleeve

cap fits the perimeter of the armscye.

This particular sequence

is likely to be followed if you choose to

follow the rule of thumb that a sleeve cap

should have a particular height. In her book,

Designing Knitwear, Deborah Newton

recommends that a sleeve cap for a "classic"-fitting

garment have a height equal to about two-thirds

of the depth of the armscye, a; for a loose-fitting

garment, this height should be less, and for

a closer-fitting garment, the height should

be greater (note that this fits in with the

theory discussed above, that a closer-fitting

sleeve needs a deeper sleeve cap).

The final bind-off of the

sleeve cap is often fixed between 2 and 6

inches; less for smaller sizes, more for larger

sizes, and less for closer-fitting garments,

more for looser-fitting garments. If the corners

produced by the bind-off are to be softened

by a few sets of bind-off rows, choose a narrower

final bind-off.

When the rest of the sleeve

cap is drafted, the aim is to have a sleeve

cap perimeter that is at least the same measurement

as the armscye perimeter. The sleeve cap perimeter

may be about 1 inch greater than the armscye

perimeter without causing any difficulties

in sewing up, so don't worry about being precise;

the extra fabric can be eased in invisibly.

Just don't design a sleeve cap that is too

small to fit within the armscye perimeter.

There is obviously some

uncertainty or at least some recursive tweaking

done with sleeve cap decreases to get the

sleeve to fit the armscye properly. This method

is most easily accomplished if graph paper

ruled to match the knitting gauge is used

-- the outline of the sleeve cap can be sketched,

then measured with the edge of a measuring

tape to confirm the sleeve cap perimeter measurement.

The outline can then be converted to actual

knitted stitches by tracing over the closest

gridlines.

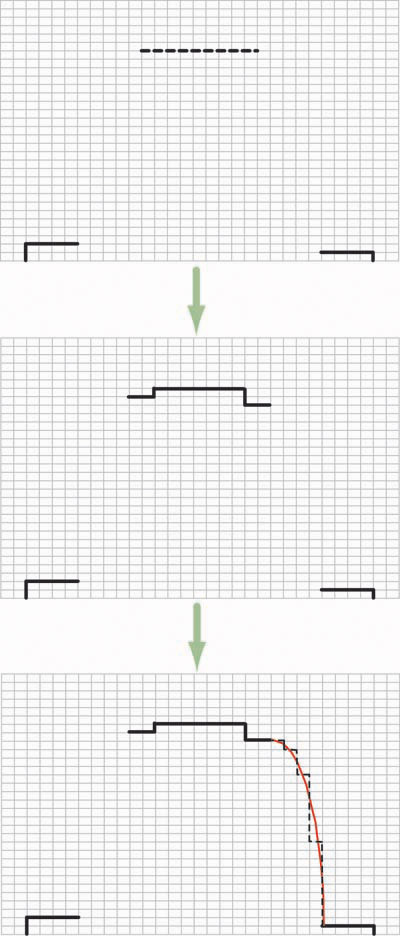

|

| The height-first

method. First, the height is chosen based

on the armscye depth; then the final bind-off

row(s) is (are) added; then the remaining

part of the sleeve cap is sketched by

hand to fit the armscye perimeter. Once

the sketched perimeter measurement matches

the armscye perimeter, the outline is

resolved according to the gridmarks. |

Other designers might follow

this order:

-

Fix the number of stitches

for the final bind-off of the sleeve cap.

-

Decide how to work the

decreases to fit between the initial bind-offs

and the final bind-off so that the sleeve

cap fits the perimeter of the armscye.

In this case, the final

height of the sleeve cap is an unknown variable,

and the designer doesn't really care what

it is, as long as the sleeve cap perimeter

fits and looks like a sleeve cap. The final

bind-off rows are chosen in accordance with

the same rules of thumb as the first method.

If this second method were

to be applied to graph paper, then it would

probably wind up being implemented the same

way as the first method -- a cap height would

have to be chosen first, otherwise the graphing

step would not make much sense. Designers

who implement this second method likely do

not use proportional graph paper at all, but

rather use trigonometry to design a sleeve

cap with the desired bell or angular shape:

since the perimeter of the sleeve cap provided

by the initial and final bind-offs is known,

the remaining perimeter must be provided by

a series of decrease rows. The number of required

decrease rows is determined using a little

trigonometry -- a little more trigonometry

is required if the sleeve cap is to have a

bell shape, with varying rates of decreases.

|

| The variable-height

method. First, the final bind-off row(s)

is (are) determined; then, given the target

measurement for the remainder of the sleeve

cap, a set of decrease rows is devised

using one or more sets of calculations

to fit the remainder. |

Still another order of operations

is:

-

After the first two

bind-off rows in the sleeve cap, decrease

according to a set formula until the perimeter

of the sleeve cap fits the perimeter of

the armscye.

-

Bind off the remaining

stitches.

This method is effectively

the "live" method of knitting a

sleeve cap -- rather than engage in calculations

or graphs beforehand, once the first two bind-off

rows are worked, the knitter simply wings

it until the sleeve cap looks like it will

fit. The height of the sleeve cap is unknown,

and so is the width of the final bind-off.

However, there is less work to do in computing

the decreases since it follows a set formula,

typically decreasing one stitch at either

end of every other row. This means the shape

of the sleeve cap is a simple trapezoid, rather

than a bell curve. This method is safer for

looser-fitting garments, since the fit to

the body is imprecise and the width of the

final bind-off could be relatively wide.

|

| TThe final

shape of a set-in sleeve with a cap shaped

using the "live" method. Once

the initial bind-off rows are worked,

the cap is decreased at a constant rate

until the perimeter equals the armscye

perimeter. |

You can check the length

of the sleeve by measuring your total

"wingspan" -- that is, the measurement

from a first wrist, over a first slightly

bent elbow, up the arm, over the shoulder,

across the back neck, and down the other side

following the same path. Your total wingspan

should be equal to the total sleeve length

of the first sleeve (including cap), plus

the upper back width, plus the total sleeve

length of the second sleeve.

If desired, write out the

schematic or graph as knitting instructions

If the sleeve cap was designed

using the first or second method, then this

will be fairly straightforward. If you used

the third, "live" method, then you

will have to write out your instructions as

you knit.

Final notes on set-in

sleeve construction

First, if you tend to knit

your sleeves before the body, this is one

situation where it is probably better to knit

the body first. It's easier to test the fit

of the sleeve cap in the armscye if the armscye

is completed first; if it doesn't fit, only

some or all of the sleeve cap needs to be

ripped out and reknit. If the body is already

constructed, you can even test the fit of

the sleeve cap and estimate the shaping of

the remainder of the cap as you are knitting.

If the sleeve was completed first and it turned

out that the armscye did not fit the sleeve

cap, you would be faced with the choice of

ripping back the sleeve cap, or ripping back

the upper body.

On the other hand, if you

are married to the method of using your sleeves

as a giant gauge swatch, just knit the sleeves

up to the beginning of the sleeve cap. Let

them wait on waste yarn or a stitch holder

until the body is completed.

Secondly, for your first

attempt at designing set-in sleeves, it's

easier to work in flat pieces, knit from the

wrist up. It is possible to knit set-in sleeves

from the armscye downwards by using short

rows to shape the sleeve cap, and it's a rather

clever strategy. However, it's easier to understand

this technique (for example, as described

in Barbara Walker's Knitting from the

Top) once you understand how the flat

pieces fit together.

You might also wonder about

selvedge stitches: should they be included

in your calculations in the sleeve cap? Generally,

if you have built in a single-stitch or half-stitch

selvedge into your garment bust measurement

and sleeve width, you can pretty much ignore

the effect of the selvedge when you are attempting

to fit the sleeve cap to the armscye. The

overall fit along that seamline will not be

affected.

Finally, what's to stop

you from simply making up a sleeve cap as

you go along, if you're designing from scratch?

Is it necessary to engage in all the computation

and sketching? No, if you don't mind knitting

and ripping repeatedly to get a sleeve cap

to fit, by all means, do it. However, if you're

trying to design for a range of sizes, you're

unlikely to want to knit a series of sleeves

and you'd probably save time by hauling out

the calculator and graph paper.