|

Ravellings on the knitted

sleeve

Part III - Set-in sleeves by the numbers

The last

time we looked at sleeves, we looked at why

set-in sleeves are shaped the way they are, and how

to make a sleeve cap to fit the armscye using either

a graph-paper method of plotting and tweaking, or

the live seat-of-your-knitted-pants method. Both of

those methods give up some amount of certainty in

the finished product in order to avoid some computational

intensity. However, some designers prefer a more mathematical

approach over repeated graphing and measurement, particularly

when a set-in sleeve cap needs to be graded (multisized)

for a pattern. This article addresses the "trigonometry"

comment in the previous sleeve article, complete with

sample numbers.

This is shaping of a bell-shaped

sleeve cap by calculation and estimation, and may

not be for everyone, although the theory is no more

difficult than the Pythagorean Theorem. (You remember

that, right? If not, there's an appendix with a refresher

course.) All that's necessary to accomplish this method

is a little time and a calculator with a square root

function -- if you're sitting at your computer reading

this article, you've got both.

If you really don't want to follow

along, jump down to Quicker fixes

to completely avoid all the computation, and read

a bit about software, short rows, and top-down construction.

The plan

|

Rules

of thumb

You

may recall some of these rules from the last

column on sleeves:

-

The

tighter fitting the sleeve and armscye,

the deeper the sleeve cap needs to be. Conversely,

the looser fitting the sleeve and armscye,

the shallower the sleeve cap will be.

-

The

armscye has a vertical depth (from the initial

bind-off row to the beginning of the shoulder)

and a horizontal depth or indentation (determined

by the number of stitches bound off or decreased).

The greater the vertical depth with respect

to the horizontal indentation, the shallower

the sleeve cap will be.

-

The

final bind-off row on a knitted set-in sleeve

cap usually ranges from 2 to 6 inches. The

narrower the sleeve cap, the shorter the

final bind-off row will be; it follows,

therefore, that with a looser-fitting garment,

the sleeve cap will be shallower so the

final bind-off row will be wider.

All

of the measurements here are presented in inches,

without centimetre equivalents -- there are

enough numbers in this article without including

conversions.

|

As discussed in the last

sleeve article, there are different strategies

available to plan the shape of a set-in sleeve cap.

You need to begin knowing the maximum width of the

sleeve, and the initial bind-off depth at the start

of the sleeve cap. After that, you can decide on the

sleeve cap height first and create the rest of the

cap to fit, or you can decide on some or all of the

remaining decrease rates and allow the height to be

determined that way. In this procedure, we'll establish

the numbers for all the bind-off rows first, then

the decrease rates, and worry about sleeve cap height

last. The sleeve cap will have a bell curve, and it

will likely (but not necessarily) have multiple bind-off

rows leading up to the final bind-off row.

We'll proceed in this order:

-

Set up the sleeve cap with an

initial width and known bind-off measurements

-

Determine the perimeter of the

body armscye

-

Determine a first approximate

decrease sequence to fit the armscye

-

Refine the decrease sequence

to create typical set-in sleeve cap curvature

-

Check measurements, and revise

step 4 if necessary

-

Determine the sleeve cap height

and design the remaining part of the sleeve

In order to shape the sleeve cap,

we need to know the shape of the armscye first. We'll

work with a hypothetical women's pullover with a 40-inch

finished bust measurement and a shoulder width of

15 inches, worked at a gauge of 4 stitches and 5 rows

per inch and intended to be worn with about 2" of

ease. This hypothetical pullover has identically shaped

front and back armscyes, which is normal in hand-knitted

clothing (it also makes the calculations easier).

In this example, both the front

and back armscyes are shaped with the following instructions

(these instructions leave out the neck shaping):

Bind off 4 sts at beg next 2 rows.

Dec 1 st ea side for next 2 rows.

Dec 1 st ea side every other row 4 times.

Work even until armhole measures 8 inches.

|

| Dimensions of the

sweater front (and back) to be fit with a set-in

sleeve. |

This decreases the armscye a total

of 10 stitches on each side (that's equal to an indentation

of 2.5 inches), and provides an armhole depth of 8

inches.

Some knitters may take the 8-inch

depth to include the bind-off rows, which means that

a further 28 rows should be worked after the bind-off/decrease

instructions are completed (28 rows even + 12 rows

of decreases and bind-offs = 40 rows, which at a gauge

of 5 rows per inch is 8 inches).

Others may choose not to include

the two bind-off rows, which means that a further

30 rows should be worked. Provided you're not working

at a terribly bulky gauge, two rows won't make much

of a practical difference.

In this example, we won't include

the bind-off rows, or in other words, "work even for

a further 30 rows".

1. Set up the sleeve cap

with an initial width and known bind-off measurements

|

| Initial values set

for the sleeve cap. |

Some numbers need to be arbitrarily

fixed. First, the width of the sleeve before

the cap shaping must be set. Some general

rules of thumb set the ease of a sleeve between 50%

and 100% of the ease around the body; in our case,

that would be between 1 and 2 inches around the upper

arm.

We'll say that the wearer would

have a 12-inch upper arm circumference, and set the

width of the sleeve at 14 inches and add a one-stitch

selvedge on either side, which is equal to 58 stitches

at a gauge of 4 stitches to 1 inch. (In this methodology,

the selvedge stitch is not treated any differently

than the rest of the stitches for the purpose of calculation.)

Next, in this method, we need to

fix the final bind-off width. Because

we're also planning to have multiple bind-off rows

at the top of the sleeve cap, the final bind-off width

can be on the narrow side; we'll choose 2.5 inches,

which at our gauge will be 10 stitches. This arbitrary

value is something that you'll come to set according

to your own preferences.

However, if the sleeve is starting

with an even number of stitches right before the sleeve

cap, then the final bind-off row should consume an

even number of stitches in order to be perfectly centred.

Similarly, if the sleeve starts with an odd number

of stitches, the final bind-off should have an odd

number as well.

|

| The

sleeve cap so far. |

Finally, the initial bind-off

width must be fixed. This will usually be

the same as the initial bind-off shaping on the body

armscye, which in this case is 4 stitches on each

side. In fact, it's almost an unwritten rule for hand

knits -- keeping the initial

bind-off at the same width as the underarm bind-off

makes setting that portion of the sleeve into the

armscye easier.

In the course of shaping the rest

of the sleeve cap, we might tweak the final bind-off

number or the sleeve width by a stitch or two in order

to get all your numbers to fit. However, the initial

bind-off width will never be changed unless we decide

to change the bind-off width on the body.

At this point, we can deduce that,

given these bind-off rows, a further 20 stitches must

be decreased or bound off on either side of the sleeve

cap.

Now it's time to calculate the perimeter

of the armscye, which is where the trigonometry comes

in.

2. Determine the perimeter of the body armscye

The armscye can notionally be divided

into different shaping zones: one for each region

having a different bind-off or decrease frequency.

We need to calculate the approximate length of the

garment edge for each of these zones. In our hypothetical

sweater, each side has four such zones:

| Zone |

Decreased/

bound-off stitches |

Number of rows |

|

| 1 |

4 stitches |

0 rows (these are the bind-off rows, and we'll

ignore their height for the purpose of calculation) |

|

| 2 |

2 |

2 ("dec 1 st ea side for next two rows") |

| 3 |

4 |

8 ("dec 1 st ea side every other row 4 times") |

| 4 |

0 |

30 ("work even until armhole measures 8 inches") |

| total |

10 |

40 rows |

First we convert these stitch and

row numbers to inches, based on a gauge of 4 stitches

and 5 rows per inch:

| Zone |

Decrease/

bind-off length |

Height (depth) |

|

| 1 |

1 inch |

0 inches |

| 2 |

0.5 |

0.4 |

| 3 |

1 |

1.6 |

| 4 |

0 |

6 |

| total |

2.5 inches |

8 inches |

Now, we need to calculate the perimeter

associated with each zone (refer to the appendix on

the Pythagorean Theorem if necessary):

| Zone |

Decrease/bind-off length |

| 1 |

1 inch |

|

| 2 |

0.64 |

| 3 |

1.89 |

| 4 |

6 |

| total |

9.53 inches |

Thus, half an armscye -- either

the front or the back half -- has a perimeter of 9.53

inches. The total perimeter of the entire armscye,

then, is 19.06 inches. This means that the perimeter

of our sleeve cap, if it is to fit the armscye, must

measure 19.06 inches as well; it may even be longer

than that, say about another inch longer, and it will

still fit into the armscye without noticeable puckering.

Therefore, we'll aim for a sleeve cap with a perimeter

that measures between about 19.06 and 20.06 inches.

Because our armscye and sleeve cap

are symmetric, we can work in terms of a half-armscye

and half-sleeve cap. Therefore, we want to create

a sleeve cap with a half-perimeter measuring between

9.53 and 10.53 inches. We certainly won't be designing

a sleeve cap to this level of precision; an approximate

number like 9.5 or 10.6 inches will be fine.

You might have figured out that

the real lengths of zones 1 and 4 are not exactly

1 inch and 6 inches, but could be more or less depending

on how the side and shoulder seams are joined. The

side seam will not be an issue, because the initial

bind-off in zone 1 will be matched by the sleeve cap

shaping, and the sleeve seam will have the same seam

allowance as the side seam. As for the shoulder seam,

that's not enough to make a significant practical

difference.

3. Determine a first approximate

decrease sequence to fit the armscye

Now, to fill in the big blanks in

the sleeve cap shaping. In this method, we'll follow

some rules:

-

No

more than one decrease per edge in any row.

For example, "dec 1 st ea side for next 4 rows"

is acceptable, but "dec 2 sts ea side for next

2 rows" is not. If your computations suggest that

you need to work more pairs of decreases than

you have available rows, then you will need to

either expand or increase the number of bind off

rows, by adding another pair of bind-off rows

at the bottom or top of the sleeve cap, or by

increasing the number of stitches bound off at

the top of the sleeve cap. The only bind-off row

that is inviolate is the initial pair of bind-off

rows: the ones that match the initial pair of

bind-off rows on the body.

-

It's preferred, but not mandatory,

to keep easy-to-follow

decrease rates on the sleeve cap,

such as every row, every other row or every fourth

row. This keeps as many decreases as possible

on the right side of the fabric, because this

seems to make instructions easier to follow for

some knitters. If it's simply not possible to

follow that rule, then go ahead and decrease on

every third row. ("Every third row" is easier

for a knitter to follow than "every second and

fourth row alternately", although "every second

and fourth row alternately" does keep all decreases

on the right side.)

-

If you find that you need to

do a lot of tweaking to your sleeve cap, and you

really need guidance on where to end one set of

decreases and start decreasing with a different

frequency, try following the general rule of keeping

the point of inflection on the sleeve

cap shape in approximately the right place.

Point of inflection?

The typical set-in sleeve cap gains

its bell-like shape from a change in the curvature

from positive to negative. This change is an inflection

point. For those of you who love calculus, no

further explanation of an inflection

point is needed. For those of you who don't, it's

the point where the sleeve cap stops being concave

upwards (around the underarm) and starts being concave

downwards (around the shoulder). For those of you

who didn't like the word "concave", the point of inflection

is the big blue dot in the diagram. See?

That point corresponds to the point

on the armscye where the decreasing stops and the

straight vertical part starts. In practice, the curvature

of a hand-knitted sleeve cap doesn't always immediately

switch to an obvious negative curvature at the point

of inflection; it just stops being obviously positive

by that point. Furthermore, the bulkier your gauge,

the less scope there is for refining the curvature

of the sleeve cap, because you simply don't have enough

stitches and rows to follow a precise curve. (Think

of intarsia--if you tried to knit a graphic design

in a fixed area, you get a lot more detail if you

knit at a finer gauge.) So, when drafting the sleeve

cap, if we take the point of inflection into consideration,

we won't aim for absolute mathematical certainty;

we'll just aim to keep the point of inflection in

that neighborhood.

In our hypothetical sweater, the

point of inflection occurs at the junction of zone

3 and zone 4. So, a half sleeve cap to fit this half

armscye will curve around the underarm, but that curvature

will have stopped by the time the perimeter equals

3 inches.

Now, how would these underarm and

shoulder curvatures be represented in knitting? If

you described the underarm curvature in words, you'd

say that it starts out flat, begins a shallow curve,

and gradually climbs so that the angle gets steeper

and steeper. The shoulder curvature starts out steep,

but gradually eases off to be shallow, then becomes

totally flat at the final bind-off. If you described

it in numbers, in our bell-curve-like sleeve cap you'd

say that the tangent of the sleeve cap curve starts

at zero degrees and increases to a maximum angle,

then decreases again to zero. Either way, in the context

of knitting a sleeve cap:

-

A flat line (zero degree tangent)

corresponds to a bind-off.

-

A very shallow curve corresponds

to multiple decreases in each row(preferably,

a bind-off row or two).

-

A shallow curve corresponds

to one decrease in every row.

-

As you reduce the frequency

of decreases to one decrease every other row,

to every three rows, four rows, etc., the curve

becomes progressively less shallow, or progressively

steeper.

Filling in the numbers: first

attempt

First, let's add a little more shaping

to the top of the sleeve cap. We've already fixed

a final and an initial bind-off width. If you were

to picture the sleeve cap in your mind's eye at this

point with a constant decrease rate between the bottom

and top of the sleeve cap, you could imagine that

there'd be a rather sharp corner at the very top --

not very curvy. This is one area where we'd like a

very shallow curve, so we could add some further,

shorter bind-off rows leading up to the final row

to soften the angle.

A good first attempt for this area

is to add 50% of the final bind-off width to either

side of the final bind-off row, and to split this

50% over a couple of bind-off steps -- maybe evenly,

or maybe in a roughly two-thirds/one-third proportion.

In our hypothetical sleeve cap, we had a final bind-off

of 10 stitches (2.5 inches), so we'll add some more

bind-off rows that remove a further 5 stitches (50%)

on either side. And we'll split that up over a couple

of steps, which in this case is 3 stitches + 2 stitches.

If you graphed this sleeve cap, it would look like

this [see below]: (if you were using this method of

calculating sleeve cap shaping, you likely wouldn't

bother plotting it out; these graphs are provided

for illustration)

|

| Graphed schematic

of the sleeve cap after estimating the final bind-off

rows (this graph is to scale, but the total height

of the sleeve cap at this point is only an estimate). |

The corresponding sleeve cap instructions

would read like this:

[instructions from wrist to sleeve cap shaping]

58 sts on needle.

Bind off 4 sts at beg of next two rows.

[decrease instructions to be filled in]

Bind off 2 sts at beg of next two rows, then 3 sts

at beg of foll two rows.

Bind off remaining 10 sts.

We're now left with 15 stitches

to decrease on either side of the sleeve cap. We need

to figure out how to do that, while keeping the half-perimeter

of the sleeve cap between 9.53 and 10.53 inches.

Each half sleeve cap has

an initial bind-off of 4 stitches (equal to 1 inch

of the perimeter) and a final bind-off of 5 stitches

at the very top (equal to 1.25 inches). We've now

added further bind-offs of 5 stitches over 4 rows.

In terms of inches, that's a length of 1.25 inches

over a height of 0.8 inches. The approximate perimeter

measurement of this segment is about 1.48 inches.

Therefore, in total, the bind-off rows in the above

diagram take up about 3.73 inches of a half-sleeve

cap perimeter (1 + 1.25 + 1.48 inches). This means

that the remaining part of the half-sleeve cap, in

which the 15 stitches must be decreased, must cover

a length of between 5.8 inches (9.53 - 3.73 inches)

and 6.3 inches.

|

| Calculating the number

of rows available for the remainder of the sleeve

cap shaping. |

For a first estimate, we'll calculate

what average decrease rate will give us the perimeter

we need. 15 stitches to be decreased is equal to 3.75

inches of width. If this was one short leg of a right

triangle, and the 5.8 inches was the hypotenuse, then

the height of that triangle would be approximately

4.42 inches. In our gauge, that's 22.1 rows (we'll

make use of some of the half inch of tolerance we

have in determining the perimeter of the sleeve cap,

and round that up to 23 rows). In other words, then,

if we decreased 15 stitches more or less consistently

over 23 rows, we'd fit our sleeve cap.

To figure out the decrease frequency,

we'll divide 23 rows by 15 stitches to arrive at 1.53

rows per stitch: in other words, if we worked a decrease

approximately every 1.5 rows, we'd fit our target

perimeter measurement. In this case, decreasing one

stitch every 1.5 rows is the same as decreasing 2

stitches every three rows, or something like "decrease

1 st every other row and every row alternately". If

we used this decrease, the instructions would look

like this:

[instructions from wrist to sleeve cap shaping]

58 sts on needle.

Bind off 4 sts at beg of next two rows.

Decrease 1 st ea side every other row and every

row alternately until 20 sts remain.

Bind off 2 sts at beg of next two rows, then 3 sts

at beg of foll two rows.

Bind off remaining 10 sts.

Now, we could stop there, and use

this type of decrease for our sleeve cap. We'd wind

up with a relatively simple trapezoidal shape, and

if plotted on proportional graph paper, it would look

like this:

|

| A first estimate

for a sleeve cap. |

That's a roughly 5.4 inch high sleeve

cap. And it doesn't look too bad for a first attempt.

4. Refine the decrease sequence

to create typical set-in sleeve cap curvature

Even though the first attempt at

a sleeve cap looks pretty good, it's not the best.

We could leave the sleeve cap as is and move

on to the next step, but from a pattern-writing perspective,

working decreases "every other row and every row alternately"

is annoying to write and frustrating to follow. Also,

depending on fitting preferences, this sleeve cap

might look too shallow or seem a little too trapezoidal.

If the decrease rate was the only

concern, we could address it by splitting up the every-row

decreases and every-other-row decreases, so that every-row

decreases are worked first, and the decreases every

other row second. Currently, our "decrease 1 st ea

side every other row and every row alternately until

20 sts remain" instructions result in 8 every-other-row

decreases, and 7 every-row decreases. If all the every-row

decreases were worked first, the sleeve cap edge would

look like the outline on the left, below. But we could

also work all the every-other-row decreases first,

as shown in the middle outline. We could even split

up the decreases, and work some every-row decreases,

then the every-other-row decreases, and then the rest

of the every-row decreases, as shown below.

|

| Changing the arrangement

of the decreases: placing the higher-frequency

decreases first (left), second (middle), and before

and after the lower-frequency decreases. |

So how would we divide up these

decreases? If our objective is a shape resembling

a bell curve, we can see by comparing the outlines

above that the rightmost shape is the most desirable;

from the initial bind-off, the sleeve cap begins with

a shallow curve, gets steeper, then tapers off with

another shallow curve before the final bind-off row.

If we used this shape, our instructions would read:

[instructions from wrist to sleeve cap shaping]

58 sts on needle.

Bind off 4 sts at beg of next two rows.

Decrease 1 st ea side every row 4 times, then every

other row 8 times, then every row 3 times.

Bind off 2 sts at beg of next two rows, then 3 sts

at beg of foll two rows.

Bind off remaining 10 sts.

We could take that and move on to

the next step. But if you're more obsessive than this,

and you really wanted to read the words "point

of inflection" again, we could try to place that transition

from every-row to every-other-row decreases at the

approximate point of inflection.

To figure out how to make the decrease

frequency change at the point of inflection, first

we need to figure out what portion of the perimeter

leads from the underarm to the inflection point. As

we figured out earlier, that portion of the perimeter

is 3 inches; the first inch of that consists of a

bind-off edge, both on the sleeve cap and the armscye.

This means that the first set of "decrease 1 st ea

side every row" must be carried out over enough rows

to equal a perimeter of 2 inches. To do this, we'd

figure out the approximate length of a single decrease

over a single row (that's the diagonal of 1 stitch

and 1 row, which at our gauge is equal to about 0.32

inches), and figure out how many of those lengths

go into 2 inches (the answer is approximately 6.25;

let's round that down to 6). This means that 6 of

the every-row decreases would be worked first, then

the set of every-other-row decreases, and then the

last every-row decrease would be worked again:

[instructions from wrist to sleeve cap shaping]

58 sts on needle.

Bind off 4 sts at beg of next two rows.

Decrease 1 st ea side every row 6 times, then every

other row 8 times, then every row once.

Bind off 2 sts at beg of next two rows, then 3 sts

at beg of foll two rows.

Bind off remaining 10 sts.

We've eliminated the annoying decrease

instructions, and we've given the sleeve cap a more

bell-like curve. If there are other things to be tinkered

with, such as the sleeve cap height, this is the time

to do it. Remember that we can add up to about half

an inch to each side of the sleeve cap without seriously

affecting the assembly of the sweater, so an easy

way to sneak in a bit more height is to simply add

a couple of rows. We'll do it in this example, just

for fun. We'll turn two of those every-row decreases

into every-other-row decreases. This will shift the

point of inflection on the sleeve cap downwards. That's

okay -- we didn't move it too far.

And while we're at it, see those

instructions to bind off 2 stitches at the beginning

of two rows? That's just silly, because while it's

equivalent to decreasing 1 stitch at each end for

two rows, it has the disadvantage of adding a stair-step

edge to the sleeve seam. We put those bind-offs in

when we worked on the final sleeve cap shaping; they're

not mandatory. This is a good time to turn them into

decrease instructions.

Now, our instructions read like

this:

[instructions from wrist to sleeve cap shaping]

58 sts on needle.

Bind off 4 sts at beg of next two rows.

Decrease 1 st ea side every row 4 times, then every

other row 10 times, then every row 3 times.

Bind off 3 sts at beg of foll two rows.

Bind off remaining 10 sts.

And our sleeve cap looks like this:

|

| The final sleeve

cap (we hope). |

5. Check measurements, and

revise step 4 if necessary

It's not necessary to check your

measurements over again if you simply used that first

approximation of the sleeve cap. In this example,

it probably isn't even necessary to double-check that

the sleeve cap perimeter is no more than an inch longer

than the armscye perimeter--all we did was rearrange

some decreases, then stick in a couple of more rows.

However, if you do any further tweaking, and if you

decide to alter the width of bind-off rows, or adjust

the height of the armscye or the width of the sleeve

before the sleeve cap shaping, it's a good idea to

make sure that the sleeve cap will still fit the armscye.

You may find that you need to undo some of your tweaks.

6. Determine the sleeve

cap height and design the remaining part of the sleeve

We're just about done. All that

remains is to figure out how to knit the rest

of the sleeve, which is a lot easier than what we

just did. For this, we need to know the total length

of the sleeve, and the width at the bottom. This is

covered in the first

and second

sleeve articles.

And that's it.

Quicker fixes: software,

short rows, and knitting from the top down

You can avoid the entire process

of calculating armscye and sleeve cap shaping on your

own by using software designed to

generate knitting patterns based on your input measurements.

It's up to you whether the savings in labour is justified

by the expense.

Depending on your design needs,

some knitting software may not give you the degree

of control that you want over the precise fit and

silhouette of a set-in sleeve. You'd need to explore

each program's capabilities to see if you can adjust

the sleeve cap height or final bind-off width, for

example. If possible, try a demo version of the software

first, to see if it will generate the type of set-in

sleeve that you want.

Next, a word on being clever with

short row shaping on a sleeve cap:

you may be familiar with short-rowed

shoulders, which make seaming slanted shoulders

a snap by eliminating the stair-step effect caused

by repeated bind-off rows. It might occur to you to

do the same thing with a sleeve cap worked from the

bottom up, since a smooth edge is easier to work with

than a jagged edge, and in fact, it's a good idea.

However, you need to exercise caution:

working short rows creates an angled line of live

stitches (a hypotenuse, if you will), longer than

the width of the same number of stitches worked straight

in an unangled row. Finishing a series of short rows

normally involves knitting across all stitches,

hiding any wraps, using the same number of

live stitches. This will cause the short-rowed area

to draw in, or cup (such as in short row bust shaping).

If this happens at the top of a sleeve cap, the cap

will curve over the shoulder like a tailored suit

-- but the final sleeve cap perimeter will be too

tight to fit the armscye, unless you increase a few

stitches when knitting the final full row to flatten

the sleeve cap out to its originally intended dimensions.

If you want to deliberately curve

the sleeve cap in this manner, then the sleeve cap

will need to be resized to fit the armscye, and you

should first ensure that the shoulder seam will hit

the shoulder at precisely the right point. Otherwise,

the sleeve cap will cup too low on the arm or too

high on the shoulder, like a misplaced puffed sleeve.

And speaking of short rows, a short-row

method is used by Barbara Walker in her book, Knitting

from the Top, to create top-down set-in

sleeves that are picked up from the armscye

and worked down towards the wrist. In essence, the

stitches required to meet the maximum sleeve width

are picked up around the armscye; the sleeve cap is

shaped by beginning with a fixed proportion of stitches

centered at the shoulder, and working short rows that

consume one additional stitch at the end of each row

until the bottom of the armscye is reached. In bottom-up

terms, that's equivalent to a decrease of one stitch

at each end on every other row between the initial

bind-off rows and a single, final bind-off row. This

creates a simple trapezoidal sleeve cap rather than

a more complex bell shape.

Like the computationally intense

method we worked through above, Walker's method doesn't

bother establishing the height of the sleeve cap before

figuring out the shaping; it sets the width at the

top of the sleeve cap, and the width of the lower

horizontal portions of the sleeve cap outline, then

fills in the rest. However, unlike the method used

in this article, Walker's method is not concerned

with working a sleeve cap that matches the perimeter

measurement of the armscye; rather, the sleeve cap

is "forced" to match the perimeter measurement, because

the sleeve cap stitches are picked up around the armscye

using whatever stitch-to-row proportion is necessary

to distribute the stitches evenly among the rows of

the armscye. The sides of the sleeve cap trapezoid

fit neatly into the curved armscye portions because

the stitch gauge of the sleeve cap is distorted when

the stitches are picked up around the armscye.

The Walker top-down sleeve has a

relatively wide upper edge (the edge that would normally

be the final bind-off edge when knitting from the

bottom). In the proportions used by Walker, the upper

edge of the sleeve cap is one-third of the maximum

sleeve width. Thus, for the sleeve width in our hypothetical

sweater example, Walker's upper edge would measure

about 4.7 inches straight across, whereas we had 2.5

inches (softened with a further pair of bind-off rows).

Strictly following Walker's methodology also yields

a strange result: you'd discover that the narrower

the sleeve, the shorter the sleeve cap will be, and

the wider the sleeve, the longer the sleeve cap will

be. This contradicts the general rule of thumb that

a close-fitting sleeve should have a deeper sleeve

cap. Theoretically, the effect of strictly following

the Walker method in a tight, short sleeve

would be a sleeve hem that does not fall horizontally

across the upper arm; instead, the sleeve fabric would

be stretched by the bulk of the shoulder and upper

arm, and the sleeve hem would appear curved or arched

over the upper arm. (This might produce the impression

that your upper arms are either muscular or fat. But

that depends on your own perspective.) Such fitting

concerns could be addressed by altering the proportions

of the stitches picked up around the armscye, and

changing the lengths of the short rowsto produce a

more rounded cap.

References

Walker, Barbara, Knitting from the

Top [Schoolhouse Press, 1996].

And see the references in the previous

two Thinking Beyond the Pattern columns on sleeves

[1,

2].

|

Appendix:

Pythagoras says...

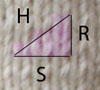

In a

right-angled triangle, the square of the length

of the hypotenuse (H) is equal to the

sum of the squares of the other two sides (S

and R). In the diagram to the right,

you can see that the squares of the two shorter

sides is equal to the square of the longest

side (9 + 16 = 25).

So,

if you've got your trusty calculator, here's

how you'd figure out the following numbers:

1. If

you know S and R, figure out H

like this:

-

calculate

the square of each of S and R

-

add

the square of S to the square of

R

-

take

the square root of that result to get H

Most

calculators will give you the answer if you

press these buttons: [where you see "S"

or "R", type in the number that you have

for those values]

On your

calculator, the square and square root functions

may be on the same button, and one will require

you to press a "shift" or "inv" key first.

2. If

you know H and S, figure out R

like this:

-

calculate

the square of each of H and S

-

subtract

the square of S from the square of

H

-

take

the square root of that result to get R

And

most calculators will give you the answer if

you do this:

3. If

you know H and R, figure out S

by using the same logic. The calculator instructions

would run like this:

The

Pythagorean Theorem applies handily to knitting,

because most knitting creates a grid of stitches,

in which the rows are perpendicular to the columns.

The two shorter sides of a knitted right-angled

triangle can be represented by the number of

stitches and rows; the hypotenuse, which is

the longest side, runs diagonally, and could

roughly follow an increase or decrease edge.

A slight

confounding factor arises in that the height

of a stitch usually isn't the same as the width

of the stitch, but that can be dealt with by

converting all stitches and rows to inch (or

centimeter) measurements.

|

|